Monday July 11, 2016 at 4:54pm

Jonathan Pawson, an Engineering student at Cambridge University tells us what he has been up to during his 4 week placement with Solid Solutions.

Week 2

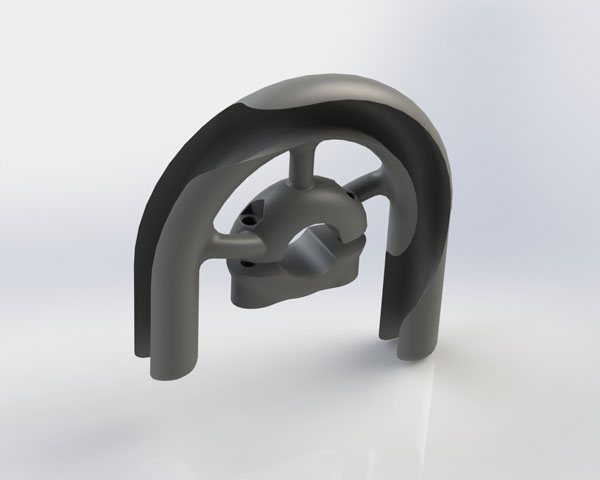

The finished prototype 3D Printed

Second week almost done and the 3D printer is currently in

the process of printing out the first prototype of the lock holder (after a few

hiccups!).

Again this week has involved more training courses; assembly

and sheet metal, which have both followed on from last week and branched out

into more specialised areas of SOLIDWORKS.

I’ve also been working a lot more on my personal project and

have developed the design up to a point where I am now printing out the first

prototype.

(The finished

prototype, mounted using hex bolts)

I’m using a MakerBot Replicator 2 to print it out. It’s very

simple to use and comes with its own software that takes the .stl file from SOLIDWORKS

and works out the path the printer extruder nozzle needs to take.

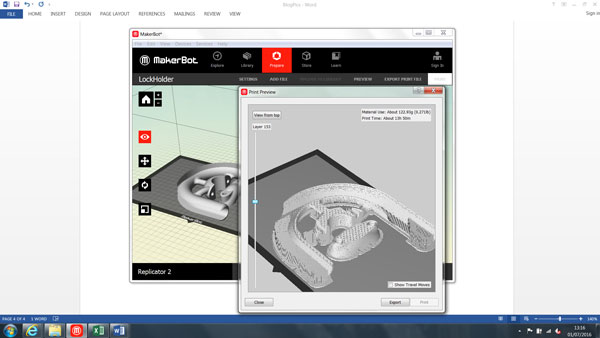

(The

MakerBot MakerWare makes it easy to position the model for printing and to

customise the print properties)

The first prototype has just been printed! It’s at a low

quality (to speed up the printing process, which still ended up being 3hrs!)

and has warped quite a bit due to its positioning on the bed (that will be

something to change for next time), but it’s happened and works well for a

first run. The hex bolts fit well and the D-lock can fit partway into it, but

doesn’t twist into it, due to the warping and the tight fit.

(The first

prototype with a D-lock, in a funky colour design because the spool ran out

part way through!)

To try and combat this problem I’ve printed it out in a different

orientation so it is standing up. The second print proved to be a lot more

successful and the lock easily fits into it.

Now

time to test it out!

Jonathan Pawson